Unique optical system to allow the film continuous high speed machining

ーGHS®Fast laser micro hole processing usingー

Regarding the converting technology, the Kansai Converting Manufacturing Study Group said, “Coating, laminating, printing on relatively thin substrates such as plastic film / sheet, metal foil, paper / paperboard, non-woven fabric, fiber, steel plate, and glass. It is defined as “a general term for acts that create new value through new processes such as.”

However, with conventional laser hole drilling technology, the pulse energy of the laser oscillator was not sufficient, and it was necessary to overlap shots at the same location in order to penetrate. With conventional galvano scanners and polygon scanners, these laser irradiation technologies have a limit in scanning speed, and laser machining of up to 3,000 holes per second was possible. Moreover, this method has a problem in performing high-speed drilling on a moving body such as roll-to-roll transfer, and requires a function to irradiate a laser in synchronization with the moving speed, resulting in high-precision optical design. And it had to be a complicated mechanism.

In recent years, high-power, high-repetition-frequency lasers with improved laser performance that enable drilling of electrode materials, plastic films, and metal foils have also been sold, and an environment for improving processing efficiency has been established. However, when the above-mentioned conventional scanner is used, the laser capability cannot be fully utilized, and about 50% or more of the energy is lost, resulting in inefficient laser processing.

In addition, with these scanners, the optical system cannot keep up with the large-area laser machining that supports a wide range of roll transfer (electrode material, film, metal foil) by repeating steps and repeats, and the speed in electrode and film manufacturing plants. In addition, there are problems such as variations in hole shape when machining large areas such as moving electrodes and films, which is far from the hole machining speed, and there are problems with both laser machining speed and quality. It was.

About the new scanner

GHS®”Grand Helical Scan” developed by WIRED

Wired was the first in the world to review the optical design from the ground up and develop a unique scanning method in order to solve the conventional problems.

It is called the ” GHS ® helical scan method ” because it has a structure that spirally irradiates the machined surface with laser light .

Furthermore, the optical energy loss is suppressed to 10% or less, and it is possible to penetrate a thickness of 200 μm or more with one laser shot. Its high-speed laser hole processing speed is 10 times faster than that of conventional scanners, and it is compatible with roll-conveyed films and has an optical design that evenly distributes light. We have realized high-speed laser drilling and the development of processing equipment that enables mass production.

Also, it should be noted that while moving at high speed, it is possible to make laser holes in specific places by making full use of advanced control technology, and it is possible to make selective laser holes on resin film and metal leaf. Decorative processing to draw a pattern is possible.

In addition, transpiration components (suspended particulate matter, fume, etc.) generated during processing can also be an obstacle in continuous processing, so it is necessary to efficiently and continuously collect dust from these transpiration components. By making this function a scanner-integrated structure, continuous laser hole machining by roll-to-roll transfer of resin film, metal foil, etc. has been realized, and in addition to trial production, production and sales of mass production processing machines have also started. ..

Please feel free to contact us after seeing the introduction of high-speed continuous fine hole drilling technology for electrodes, metal foils, resin films, and other composite films using Wired’s original high-speed scanner .

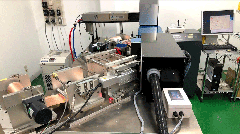

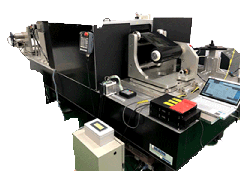

| Roll to roll laser machine | GHS®180 | GHS®360 |

| Equipment appearance |  |

|

| Original width | 150mm | 300mm |

| Processing width | 120mm | 300mm |

| Feed rate | 0.5 ~ 8m / min | 0.2 ~ 10m / min |

| Wavelength ( * ) | 355nm | 1070nm |

| * The wavelength can be changed by replacing the oscillator. | ||

Roll to Roll laser machining example

Roll to Roll

Laser Processing Machine Manufacturing

We manufacture and sell roll-to-roll laser drilling machines equipped with our original optical system GHS (Grand Helical Scan).

Laser Technical Data

Introduces laser processing technology, treatises, and laser processing examples.

Notice

We will inform you about various information, media publication information and exhibition exhibition information.