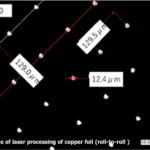

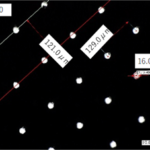

High-speed laser drilling example for copper (Cu) foil by roll-to-roll laser machining machine

This is an introduction of a case of penetrating copper (Cu) with a sheet laser machine.

Drilling was performed on Cu (t = 10 μm) with a hole diameter of 6 μm, a pitch of 30 μm (staggered arrangement), and an aperture ratio of 8.5%. WIRED Co., Ltd.