Astonishing one-time punching process with high-speed laser punches resin film and metal foil.

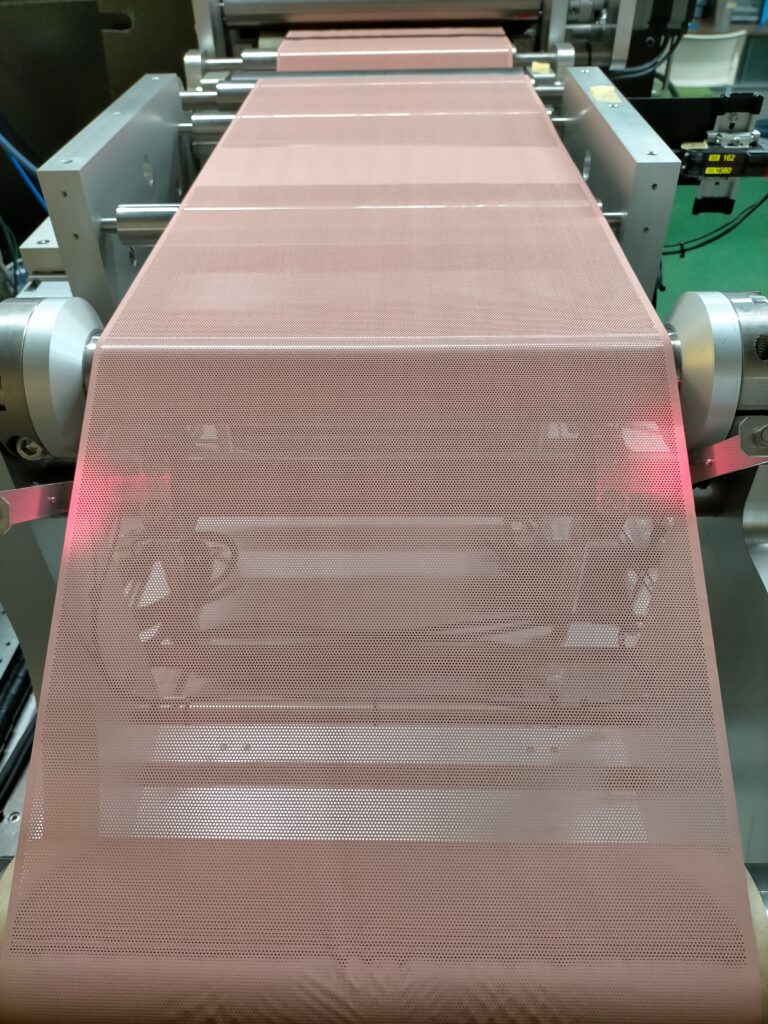

Generally, hole processing with laser relies on the beam diameter (generally φ10μm to 30μm) (laser beam is focused on a single point) or, for holes larger than the beam diameter, a circular beam scanning method is used to process holes. But the method of scanning the laser beam in a circular pattern is time-consuming and much less productive compared to, for example, a press punch process. However, even for the press punching method, the hole processing of resin film and metal foil is a highly advanced technology that requires expertise in die manufacturing, maintenance, punching technology, and so on. WIRED’s laser punching technology (high-speed laser punching) is a unique technology that solves such weaknesses of laser processing and press punching in innovative ways. It is possible to continuously perform punching of resin film and metal foil conveyed roll-to-roll in an instant, just like a press punch. No need to consider the clearance between the punch and the die, and no need to worry about maintenance of the punch. High-speed punching technology eliminates the need for die maintenance.

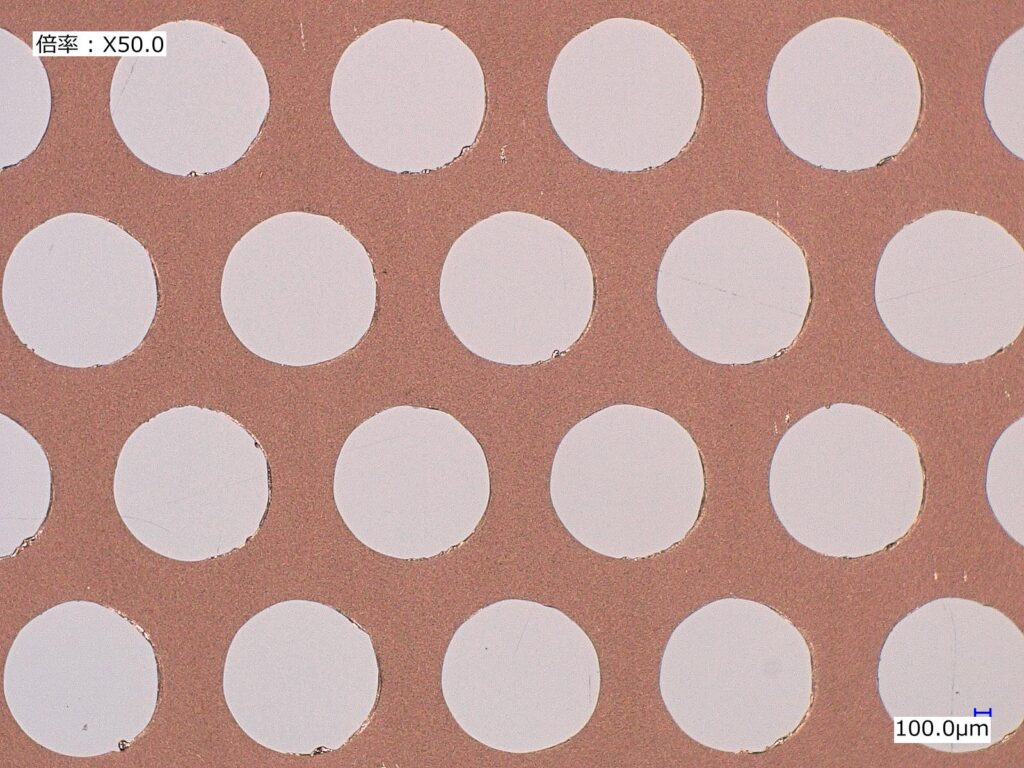

Ⅰ.Example of hole punching with a hole diameter of 1 mm and an aperture ratio of 40% for a copper foil (t = 15 µm) with a substrate width of 300 mm.

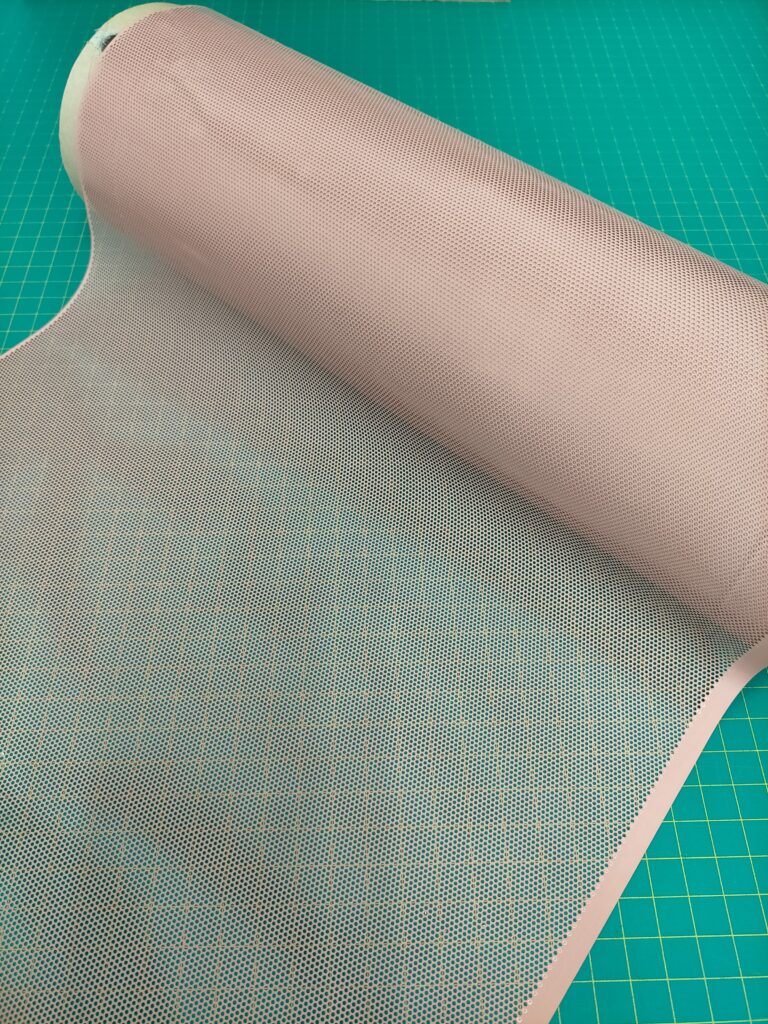

Ⅱ.Copper foil with punching process Transparent aperture ratio

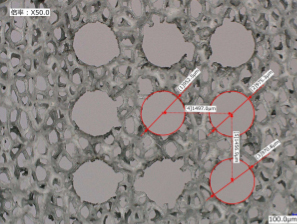

Ⅲ.A photo of the punched-out shavings: the shavings look as if they were punched out by a press punch. Wish these were gold coins.