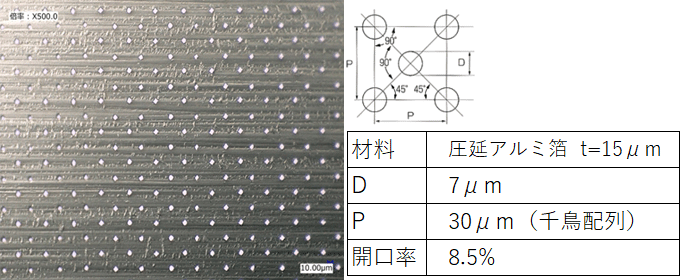

Example of drilling holes in aluminum (Al) foil using a sheet laser machine

A through hole with a hole diameter of 7 μm, a pitch of 20 μm (staggered arrangement), and an aperture ratio of 8.5% was machined on an aluminum foil with a thickness of t = 15 μm using a sheet laser machine.

Roll-to-roll transport of thin aluminum (Al) foil may cause problems such as wrinkles.

Moreover, fusion with laser processing is a more difficult technology due to the influence of heat.

Wired has solved those problems.

”Fusion of Converting technology and laser Processing technology”

Accurate and regular high-speed laser microhole machining has been achieved while transporting aluminum (Al) foil.

Click here for an example of high-speed drilling of aluminum (Al) foil using a roll-to-roll laser machine.

Laser Processing Services

Our laser processing technology enables high-speed, non-contact processing of fine holes with significantly smaller diameters and fewer burrs compared to other drilling methods such as punch presses and etching.

Laser Processing Machine Manufacturing

We manufacture and sell roll-to-roll laser drilling machines equipped with our original optical system GHS (Grand Helical Scan).

Notice

We will inform you about various information, media publication information and exhibition exhibition information.