Laser mass production processing machine for reducing manufacturing costs and high performance of batteries in the current collector hole processing of next-generation secondary batteries

■Project Title:

Enabling in-line machining of current collector holes for next-generation secondary batteries Development of Laser Mass Production Machine

processing

■Target downstream industries

Automobiles , Electronics■Research system

Wired Co., Ltd., Itagakikinzoku Co., Ltd., National Institute of Technology, Nagaoka College, Industrial Research Institute of NIIGATA Prefecture, Kanagawa University, Niigata Industrial Creation Organization,

Project Overview

Background and Purpose

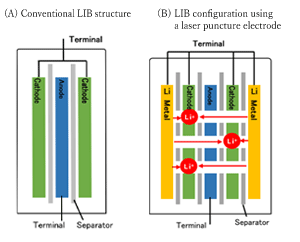

Secondary battery such as a lithium ion battery (LIB), and the power storage device such as a lithium ion capacitor (LIC), a roll-shaped current collector subjected to fine hole processing by etching or the like is used.

In the current hole processing method, it is not possible to inline in the battery production process, and because there is a limit to the minimum pore diameter that can be processed, there is a big problem to realize the reduction of manufacturing cost and the high performance of the battery.

Implementation items

-

-

- Development of high-speed wide current collector laser processing equipment

Development of a high-speed, wide current collector laser processing system (stand), and Examination of laser processing conditions for high-speed and wide current collector, and Development of processing equipment (processing section), and

Development of burr, prevention of oxide dropout, and deflection correction mechanism Development of an in-line defect detection mechanism. - Grasp and evaluation of current collector processing conditions

・Preparation of current collectors for LIC testing, and LIC performance tests, and

Performance evaluation by the manufacturer, and Next-generation LIB performance test.

- Development of high-speed wide current collector laser processing equipment

-

Products and services that can take advantage of the results of the project

-

- Laser multiple exposure Roll to Roll drilling technology

- Laser Multiple Exposure Roll to Roll Drilling Machine

Roll width 270 mm

Roll feed speed 10m/min - Ultrasonic Leveler

Ultrasonic cavitation processing head width 270 mm

PR points for products and services

-

-

-

- Selection of lasers and processing optical systems for high-speed processing

φ10-50μm, aperture ratio of 10%.

- Selection of lasers and processing optical systems for high-speed processing

-

-

| Traditional technology | New Technology | |||

| Roll Press Method | Etching method | Laser processing | ||

| Processing conditions | Processing speed | ~6,000 holes/sec | ~10,000 holes/sec | ~200,000 holes/sec |

| Minimum pore size | Φ300μm | Φ120μm | Φ10μm | |

| Inlining | × | × | The number of | |

| Capacitor capacity | × | × | The number of | |

| Manufacturing cost of current collectors | ¥1,000/㎡ | ¥1,000/㎡ | ¥500/㎡ | |

|

Challenges in traditional technology And How to solve problems with new technology |

|

|

|

|

What we did in the project

Research and Development Goals

We will develop a laser processing technology that can be in-line inthe hole processing of current collectors used in next-generation secondary batteries.

r&d for the production of high-performance current collectors.

| Traditional technology | New Technology | New Technology Points | ||

|

|

|

Challenges faced and problem solving

| Challenges faced | Means for problem solving | Effect by means | ||

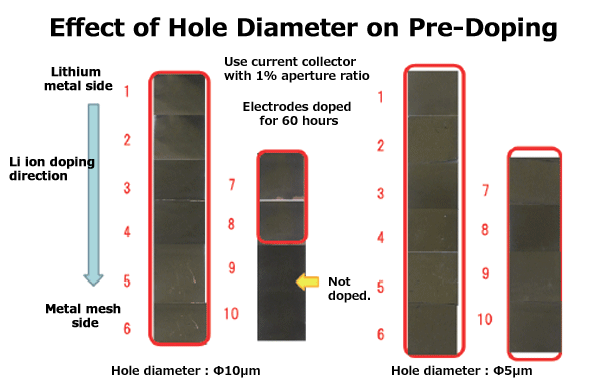

| If the irreversible capacity is too high, the battery will not function as a battery because of the loss of lithium at the positive electrode when assembled. | Lithium to erase irreversible capacity Predoping on ion electrodes |

It was confirmed that lithium ions were doped at an aperture of 4% and that the pre-doping performance was higher when the pore size was smaller. |

Results of Research and Development

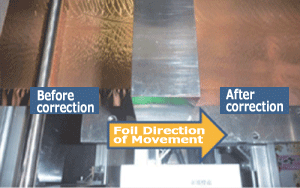

- At a feed rate of 10 m/m/ min of the metal foil, the feed accuracy has been confirmed.

- In the laser processing demonstration experiment, further efficiency processing conditions were demonstrated in nanosecond lasers, and remodeling was carried out with the aim of 10 times the processing speed.

- Completed demonstration experiments of burr removal and deflection correction equipment, leading to patent application.

- Lic performance test samples equivalent to the current product (pore size φ5~50μm) were prepared and distributed.

- In Li ion predop test of LIC performance, it was confirmed that the tendency to improve predopability even if the aperture ratio is low was confirmed.

- In the LIB performance tests, the drilling of holes in the coated electrodes has started to improve the performance of current LIBs and to investigate new batteries.

| <Problem extraction results of laser processing equipment> | |||

| Item | part | problematic point | Measures |

| Laser power | Laser Oscillator | There are no lasers on the market with sufficient power. | Design a flexible design that can be adapted to the development roadmap of the laser manufacturer. |

| Optical Design | Polygon lens, mirror, | The first prototype was designed for basic experiments, so it had a large number of pieces and a large energy loss. | The minimum mirror lens configuration design should be reflected in the design of the second and subsequent units. |

| Follow-up performance of feed mechanism |

piezoelectric element |

Adjustment is required for mirror weight and optimization. | In this project period, we will optimize the piezoelectric element specifications to increase the speed. |

Status of practical application and commercialization

Status at the end of the project

- Successful commercialization stage.

Prospects for practical application and commercialization

- Initially, the objective was to drill the copper and aluminum collector foil, but it was found that the drilling of roll electrodes coated with electrode material on the collector foil was also possible, and the perforated electrodes showed excellent battery performance.

- Developed “Ultrasonic Leveler” which corrects the deflection that occurs during high-speed processing and applied for a manufacturing method patent.

|

Corporate Information: Wired Co., Ltd. Location: 1628-1, Ichitsuyashiki, Sanjo-shi, Niigata 959-1152 URL@https://wired.jp.net/ |

Inquiries about this product and services |

Laser Processing Services

Our laser processing technology enables high-speed, non-contact processing of fine holes with significantly smaller diameters and fewer burrs compared to other drilling methods such as punch presses and etching.

Laser Processing Machine Manufacturing

We manufacture and sell roll-to-roll laser drilling machines equipped with our original optical system GHS (Grand Helical Scan).

Notice

We will inform you about various information, media publication information and exhibition exhibition information.