Installation of 4K-capable microscope for webcast of processing experiments

The COVID-19 Pandemic has changed the way we have been living.

The manufacturing industry has also been affected by the fact that business as usual is no longer acceptable. Unfortunately, face-to-face experiments are no longer possible, especially in cases where results cannot be determined without observation such as SEM photographs, which require time-consuming observation due to the limited size of the samples. In other words, it takes time to determine the processing results, which leads to the inability to develop products speedily.

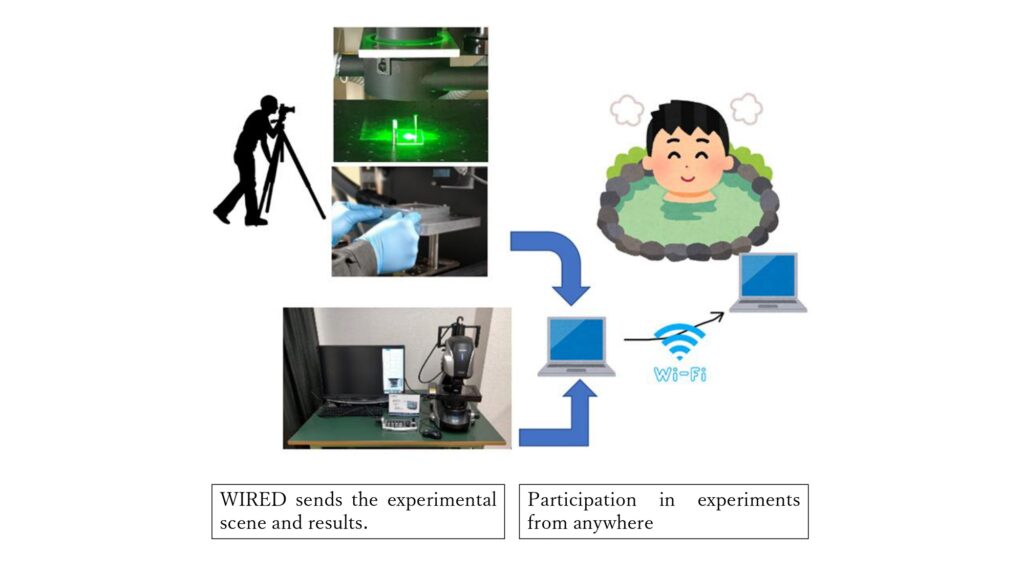

The newly installed 4K-capable microscope provides a simultaneous broadcast of the experimental scene and clear images of the processing results, making it possible for the customer to determine the processing results without leaving the office, and facilitating the planning of production technology.

By observing and analyzing the condition of the processing part, it has become possible to speedily set the optimal processing method and conditions to meet the customer’s requests. It has eliminated wasted time and increased the speed of product development.

But… sometimes waste is just as important…

Microscope

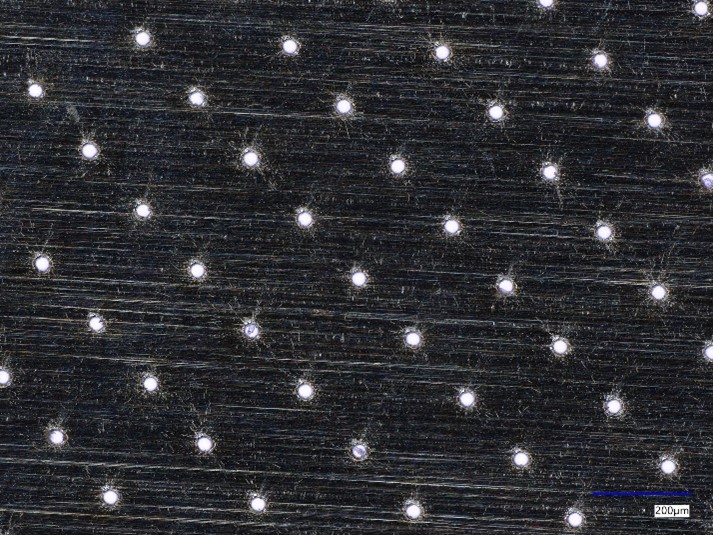

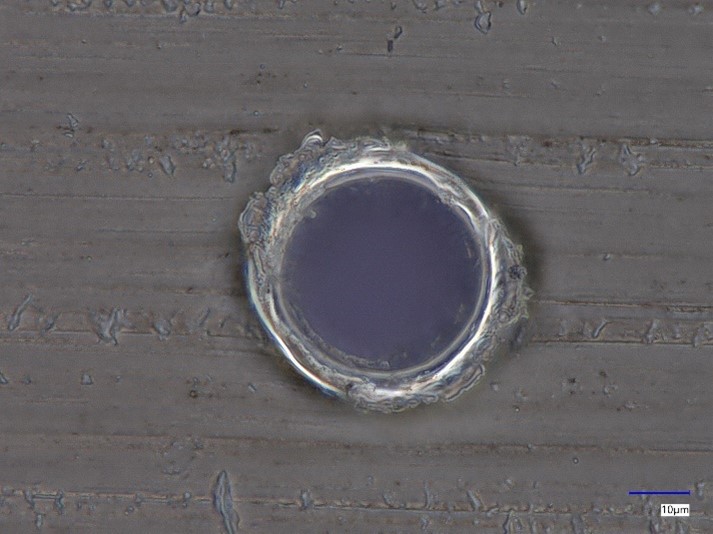

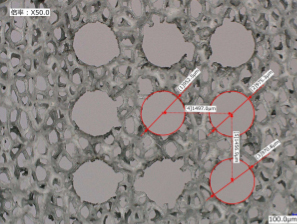

● Image taken by existing microscopes

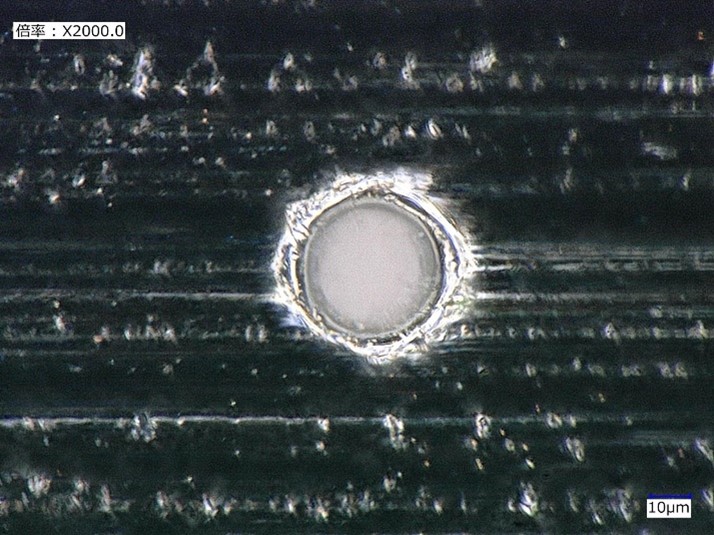

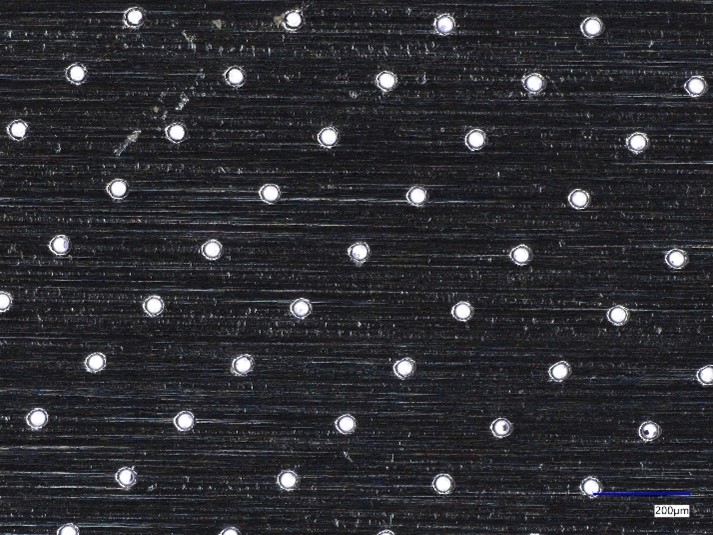

● Image taken by the newly installed microscopes.

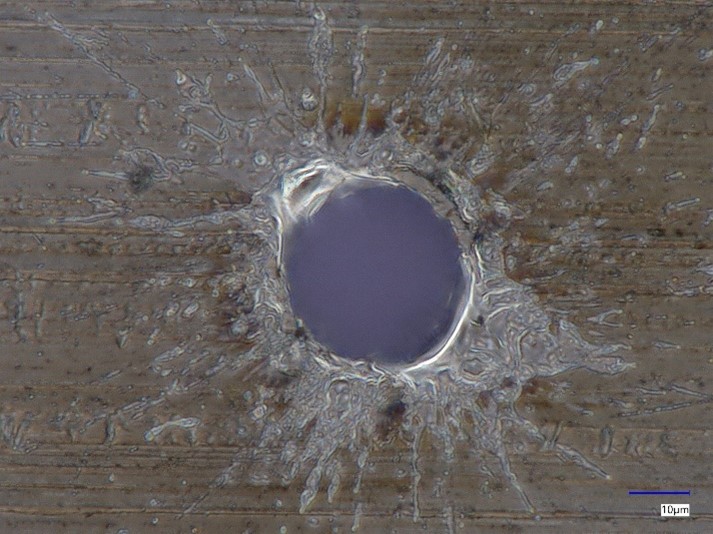

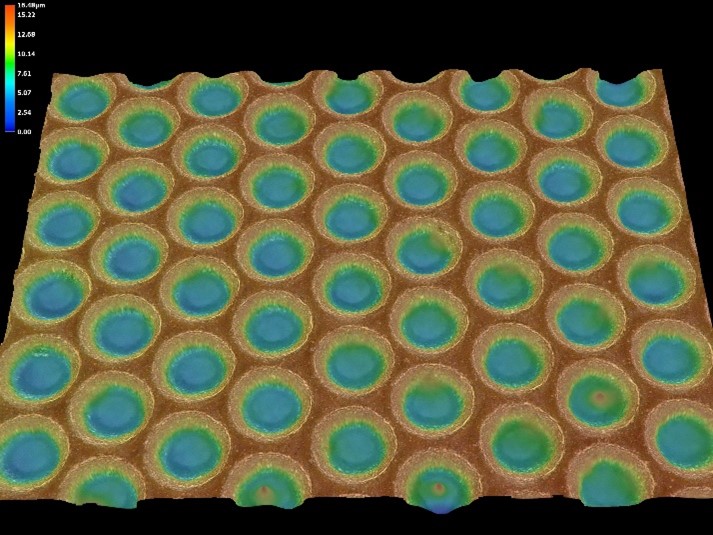

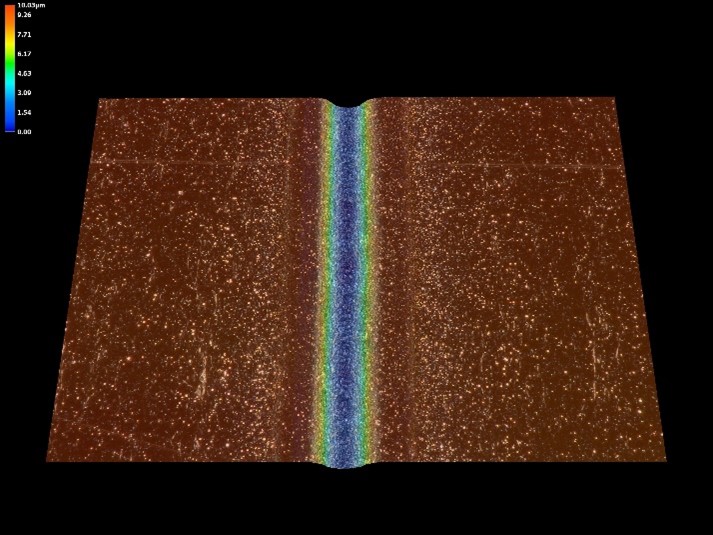

● 3D shape measurement example