Ultra-high-speed laser drilling: 100,000 holes drilled per second

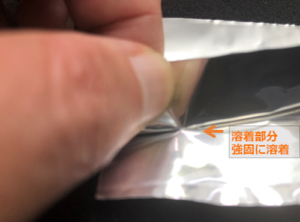

[Photo] Roll-to-roll high-speed continuous perforation of PPS film

The unique optical system GHS (Grand Helical Scan) achieves ultra-high-speed drilling by synchronizing with high-speed web handling technology. High-speed hole processing of 100,000 holes/second has been achieved on PPS film that is carried by the high speed system by roll to roll. This technology does not select materials such as aluminum, copper, and resin film that are carried by Roll to Roll.

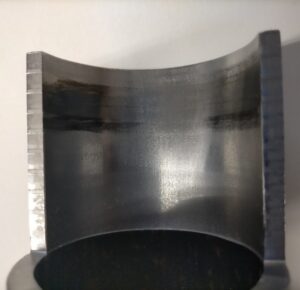

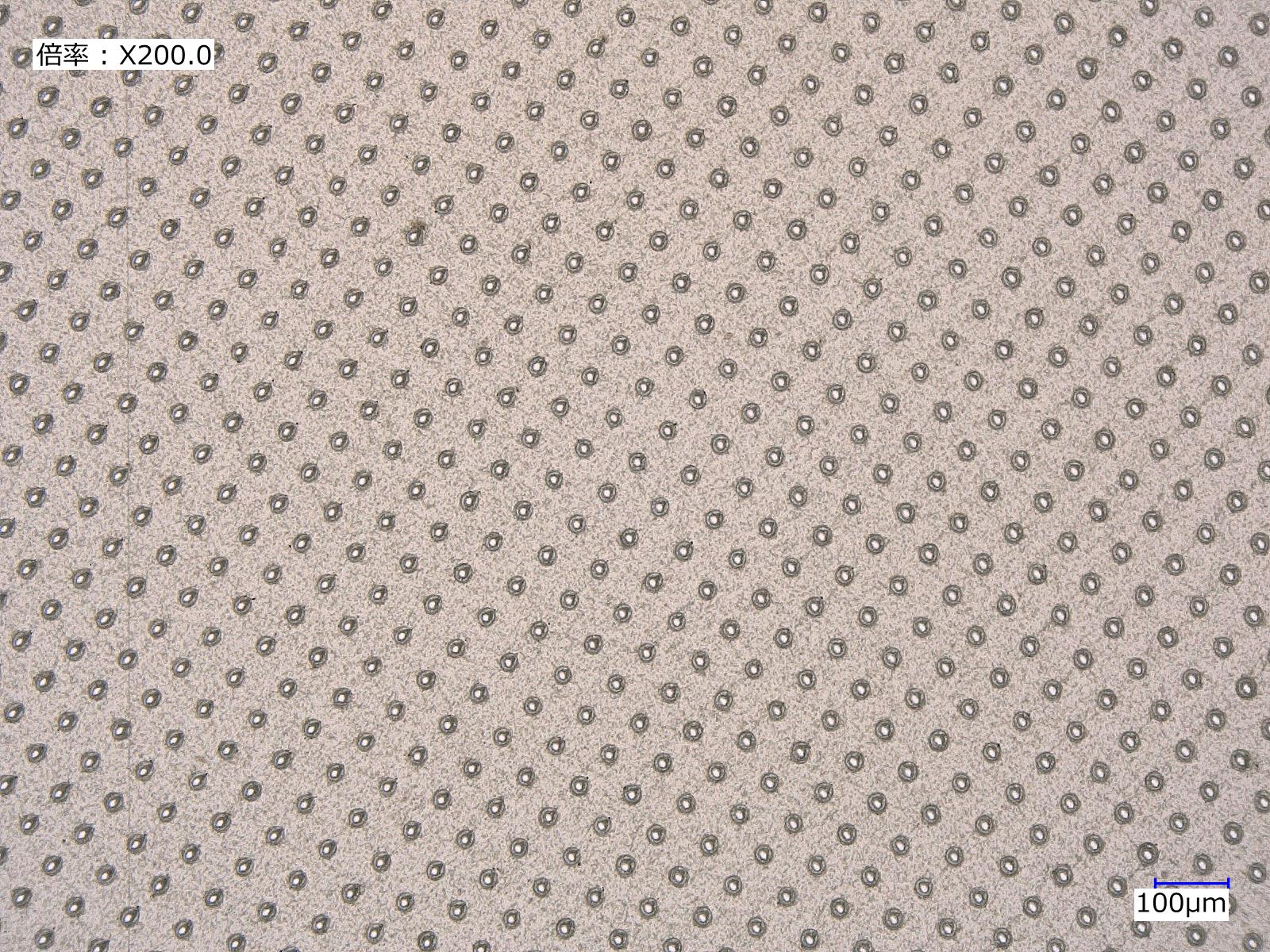

Wired’s technology, which has achieved a φ9µm pitch of 60µm aperture ratio of 1.8%, is expected in many fields as a functional film. Because the perforations are made directly on the solid film, it is expected to be stiff, strong, and difficult to open. For example, it has the potential to be used in a wide range of fields, such as the industrial sector batteries and energy, hydroponic culture, and the agricultural and food fields keep the freshness of crops.