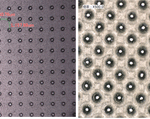

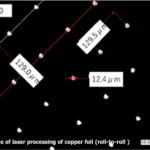

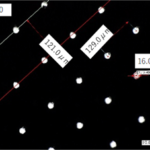

Example of drilling holes in polyphenylene sulfide (PPS) using a sheet laser machine

This is an introduction of a case of penetrating polyphenylene sulfide (PPS) using a sheet laser machine.

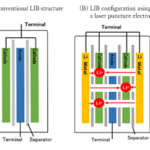

Drilling was performed on PPS (t = 25 μm) with a hole diameter of 18 μm, a pitch of 155 μm (parallel type), and an aperture ratio of 1.1%. WIRED Co., Ltd.