Reduction of irreversible capacity by laser drilling and predoping to SiO negative electrodes for lithium-ion secondary batteries (LIB)

Overview of traditional issues and research and development

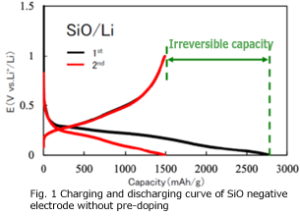

The capacity of SiO, which is being developed as a negative electrode material for lithium-ion secondary batteries (LIB), is approximately 1500 mAh/g, and is much larger than the current graphite negative electrode (371 mAh/g), so high energy density of batteries is expected.

The capacity of SiO, which is being developed as a negative electrode material for lithium-ion secondary batteries (LIB), is approximately 1500 mAh/g, and is much larger than the current graphite negative electrode (371 mAh/g), so high energy density of batteries is expected.

On the other hand, SiO has been difficult to put into practical use until now because the capacity that can actually be discharged for the initial charging capacity is small.

Through our joint research with Yamagata University, a national university corporation, we have succeeded in prototyping a battery that has significantly reduced irreversible capacity by enablin1g the SiO negative electrode with laser perforation to be charged in advance with the SiO negative electrode, which is equivalent to the predoped irreversible capacity of lithium ions in a simple manner.

Electrode configuration using laser perforated electrode

[table “44” could not be loaded /]

[table “45” could not be loaded /]

Prototype and evaluation results of small batteries

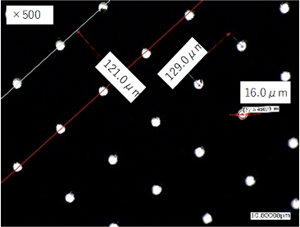

- By laser perforation of the SiO negative electrode, it was confirmed that lithium ion predopsis to SiO is possible even under the conditions of 0.5% aperture (Fig. 2, from Yamagata University-like evaluation data).

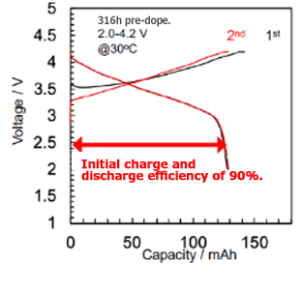

- The reverse capacity of the charge-discharge first cycle is greatly reduced by pre-doping, and the ratio of the discharge capacity to the charging capacity is 25% in the case of no predop.

In this system, it has improved significantly to 90%. - The theme of this research and development is the 59th Battery 2Symposium in Osaka, “Development of Li predoping technology in the si-based negative electrode using laser drilling technology” at the 59th Battery Symposium in Osaka.

Thanks

This result is a part of the results of the implementation of the new energy and industrial technology development organization (NEDO) of the National Research and Development Corporation.

Laser Processing Services

Our laser processing technology enables high-speed, non-contact processing of fine holes with significantly smaller diameters and fewer burrs compared to other drilling methods such as punch presses and etching.

Laser Processing Machine Manufacturing

We manufacture and sell roll-to-roll laser drilling machines equipped with our original optical system GHS (Grand Helical Scan).

Notice

We will inform you about various information, media publication information and exhibition exhibition information.