2023/7/4

/ Last updated : 2023/9/12

wired

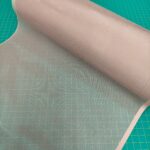

Laser cut shapes in any shape! Example 2: Half-cut on composite materials

Half-cutting is performed by cutting only Al foil of Al foil + PET laminate composite material to secure the shape. The desired shape can be continuously processed while the base material is conveyed roll-to-roll. We are capable of processing not only Al foil but also Cu foil and other composite materials and can manage a wide variety of materials and shapes. Damage to the PET material due to laser half-cutting is not a concern.