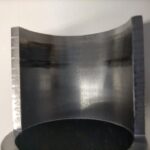

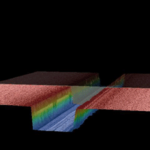

High-speed inner diameter processing optical system

WIRED’s optical technology delivers beams where laser beams cannot reach, i.e., the inner diameter. In addition, it can be applied to any type of laser. Basic waves enable induction hardening of the inner diameter, and ultrashort pulsed lasers can be utilized for laser honing. The development of laser optics has made it possible to handle inner diameters from φ50 and optical speeds of 7,000 rpm.