It was published in NICO Press (Vo.175).

Wired is engaged in a business specializing in fine laser drilling technology with the goal of “creating a new world through light!” We have realized high-speed laser drilling for various films, metal foils, electrodes, etc. by using our uniquely developed technology and know-how.

Creating a new world with fine high-speed processing technology using laser

Developed an original optical system to realize continuous high-speed drilling

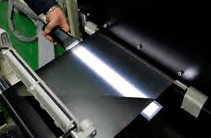

Wired is a venture company whose main business is the development of “roll-to-roll laser perforation” technology, which enables high-speed and fine hole drilling with a laser while feeding the film in rolls.

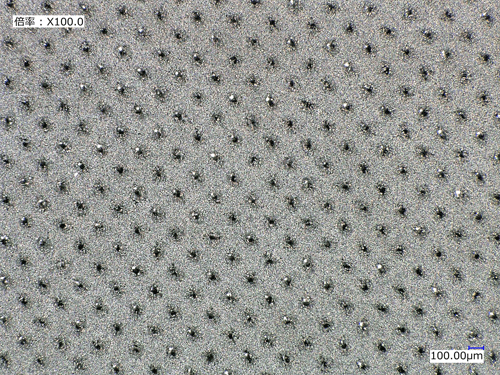

Since 2014, the company has been developing and improving roll-to-roll laser perforation processing equipment by utilizing the strategic basic technology advancement support project (support). Furthermore, from around 2016, we have been working on the development of our own optical system “GHS (Grand Helical Scan)”. “GHS is a technology that only we have in the world, and we have obtained a patent. It is possible to perform continuous drilling with high accuracy about 100 times faster than conventional optical systems, so it is a field that has not been used until now. It has become possible to utilize the above, “says Toyama.

Research by industry, government and academia to increase the capacity of lithium-ion batteries

Laser perforation, which has achieved higher accuracy and higher speed with the development of GHS, is also applied to materials other than film. One of them is the electrode of a lithium-ion battery. In recent years, the use of lithium-ion batteries has expanded and the need for higher capacities has increased. Therefore, we have collaborated with Yamagata University, Nagaoka National College of Technology, Niigata Prefectural Institute of Industrial Technology, etc. to increase the capacity of batteries. We worked on the development of laser processing technology for fine drilling, which is necessary for pulling up. “It was difficult to solve each of the problems that had to be solved at the same time,” says Toyama, but as a result of the efforts, we succeeded in increasing the capacity by about 10 times. In 2019, we delivered a laser machining device for drilling as a mass production machine, and currently, major companies are mainly developing for various machining tests and mass production.

I want to increase the technical capabilities and value of roll-to-roll laser machining

Since 2019, the company has been utilizing NICO’s next-generation industrial technology creation support project for verification toward the practical application of new silicon-based electrodes. Development in unknown fields poses a great risk, so it is very encouraging to back up NICO, which provides financial assistance, advice, and introduction of technical support organizations.

”GHS and roll-to-roll laser drilling know-how is definitely unique to us in Japan, so we would like to create a single platform with this technology. To that end, we will firmly enhance this technology to something of value. I think that is important, “said Toyama. With pride as a technology development venture company, we will continue to take on the challenge of technological innovation.

“Because we are a technology development venture, we would like to specialize in enhancing our technological capabilities and expanding their applications. We would like to create a new world with customers who find value there.” (Representative Toyama) ).

WIRED Co., Ltd.

Representative Director

Mr. Tatsushi Toyama

2-4-15 Kitashinbo, Sanjo-shi, 955-0861

TEL.0256-47-1255 FAX.0256-47-0930

URL https://wired.jp.net

Lithium-ion battery related information

High-speed laser punching technology was introduced in NIKKAN KOGYO NEWSPAPERS.

Resin related articles

Laser Processing Services

Our laser processing technology enables high-speed, non-contact processing of fine holes with significantly smaller diameters and fewer burrs compared to other drilling methods such as punch presses and etching.

Laser Processing Machine Manufacturing

We manufacture and sell roll-to-roll laser drilling machines equipped with our original optical system GHS (Grand Helical Scan).

Laser Technical Data

Introduces laser processing technology, treatises, and laser processing examples.